I have enjoyed making these Christmas ornaments for my side of the family’s Christmas party. Each of my Dad’s 60+ grands and great-grands will find an ornament in his/her stocking. These are all made with pictures from old Christmas cards. Just a side note to locals: I am always looking for more cards. If you have any to recycle or pass along, I am happy to receive them!

It’s a lot of stockings!

The ornaments are fairly easy to make. The hardest part is mastering the soldering. I am new to this hobby myself. I have done my best to write a tutorial, but have also linked to videos that help explain a few things. The initial investment is pricey for a craft you may decide you don’t enjoy. I would suggest trying a class at a craft store or sharing a craft session with a soldering friend before buying all the needed tools. See if you like the craft before making the investment.

Supply List / I’ve added links to items I am using.

- pictures

- a tile or other heat resistance surface to work over

- microscope slides

- soldering iron station

- Damp sponge (may come with the soldering iron station) or solder tip wire cleaner or a sal ammoniac block (for cleaning the solder tip)

- solder, lead free (the kind used for stained glass)

- 1/4″ copper foil tape

- flux

- paint brush for flux application

- small container to hold a little flux while you work

- foil burnisher (I use the large end of a bone folder)

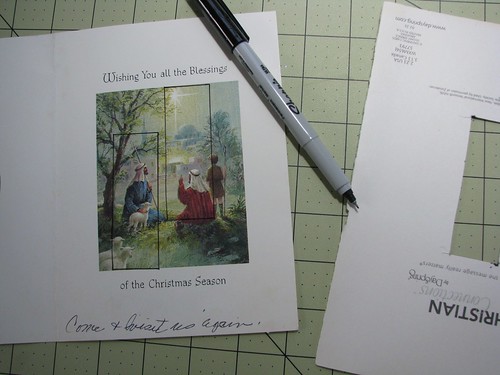

- pen or fine marker

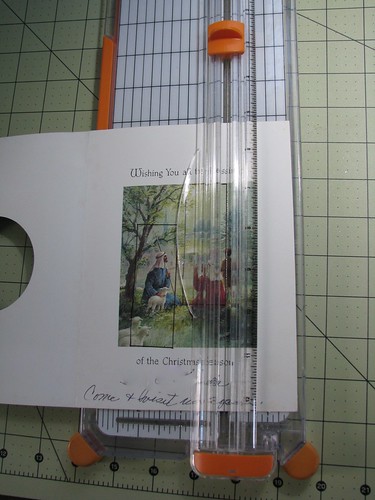

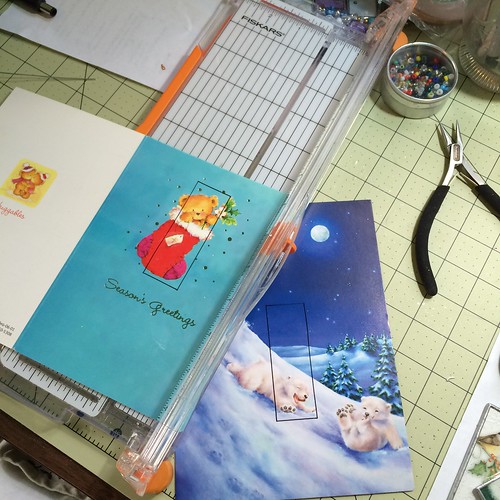

- paper cutter or scissors

- craft knife

- fine glitter

- binder clips, clamps or a “third hand“

- scissors

- jump rings – one larger size for the top and a smaller size for the bottom of the ornament if you want to hang dangles or charms / Jump rings can be bought, but are easy to make from wire.

- 20 gauge craft wire for making jump rings and for stringing beads

- flat nose or chain nose pliers

- round nose pliers

- flush cutter pliers

- beads, charms, embellishments

If using glass thicker than microscope slides, you may want to use 3/8″ copper foil tape rather than the 1/4″ foil.

I didn’t have a tile when taking these pictures, but I have since obtained a 12×12 tile. It’s a good idea to have something heat resistant to work over. I searched on amazon.com and came up with some examples of what is available.

Don’t buy a cheap soldering iron. Mine is a 40 watt iron and it works great. Get an iron that comes with a holding station. It will have a cradle where the iron can be placed when you are not using it. Keeps your work area safe from the heat, including you. And get one with a dial so the heat can be controlled. Many stations will also include a sponge for cleaning the soldering tip. And a “power on” indicator light is a great feature. Helps you remember to turn the iron off when done. When I helped my sisters solder ornaments, we found that the cheap soldering irons did not work very well. They caused a lot of frustration.

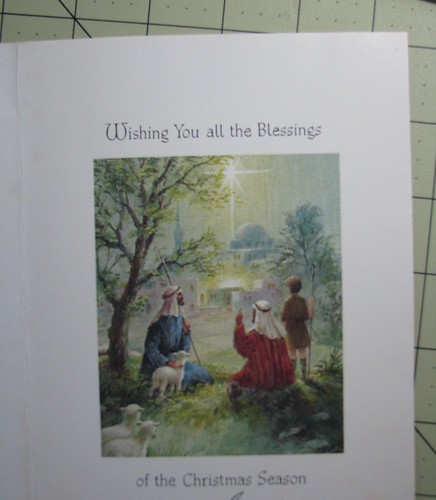

Begin by gathering the pictures to use for the ornaments. I use Christmas cards. Family photos, online pictures, scrapbook paper, etc., can be used. Scan and resize pictures, if needed.

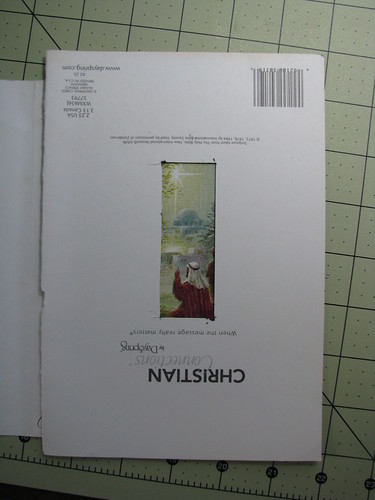

My glass slides were 3″ X 1″, so I cut a window, the same size as the slides, in the back of a card. That gave me a good way to preview the cards I was using for pictures, to see if they would work well or not.

Place the window over the picture you’ve chosen and decide which parts of the picture you will be using. I use cards that can give me two coordinating pictures. If you have a card picture and can’t make a coordinating picture with the same card, you can use wrapping paper, scrapbook paper, or other coordinating pictures to make the back.

Trace around the picture, using the window as a guide. You can use a microscope slide to trace, but be mindful of the sharp edges. I like the window because it keeps me from being distracted by the rest of the picture.

Cut the pictures to size.

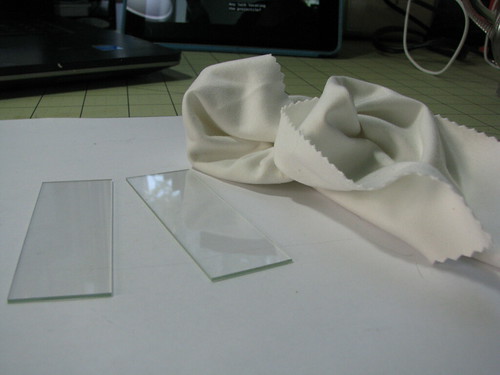

Clean the microscope slides or other glass you use. Any dirt or fingerprints left on the inside will be there to stay if not removed now. I use an eye glasses cleaning cloth to wipe the slides clean.

Sandwich the pictures between the glass. Check that both pictures are face out and that the tops of the pictures are at the same end of the glass.

Level them by putting the long side down on the work area, so the pictures and the glass pieces are even on that edge. Using a craft knife, carefully trim any excess paper from the opposite side. Turn the glass and the pictures so they are sitting on a short side and do the same, trimming any excess paper or card stock.

NOTE: I start in the middle and, while holding the slides/pictures firmly with one hand, VERY carefully cut off the excess paper, starting in the middle and slowly coming towards myself. Then I turn the slides/pictures so I can cut the second half of that side in the same manner. Craft/Xacto knives are VERY sharp. Please be cautious if you use this method to trim the pictures.

Now is the time to add a little glitter to the pictures, if you want to. No glue necessary. Use a very fine glitter.

Use the tip of your finger to sprinkle a little glitter onto the picture. Being careful not to touch the inside of the glass with your fingers, put the glass over the glittered side, turn the ornament and glitter the other picture. I find it handy to have some small object at hand that I can set the glass slide on while I glitter the picture. Setting the slide on the work space can cause it to pick up small bits you don’t want inside the ornament. Setting the slide on something also makes it easier to pick the slide back up without smudging the inside of the glass.

Cut a piece of copper foil long enough to go around the glass edges with a 1/4″ overlap. For the 3″ X 1″ slides, the foil should be cut to 8 1/4″ long.

Remove the paper from about an inch of the foil at one end. Place the glass on the center of the foil, pressing down to adhere it to the glass. Work your way around the glass, peeling the backing off the foil as you go along.

Here is a site that does a good job of explaining how to foil glass. Everythingstainedglass.com

And here is a video showing how to foil. How to Use Copper Foil Tape on Glass Pendant

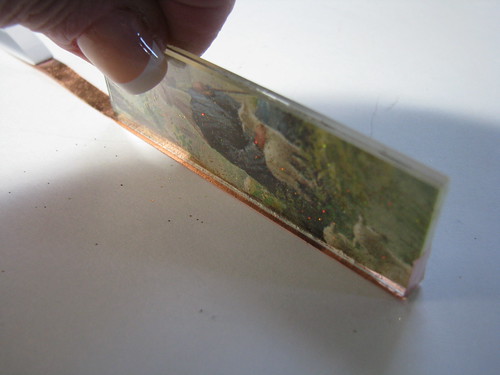

This piece has been foiled, but the foil has not been crimped or burnished yet.

Crimp (fold over) the foil so it adheres to the glass. Start in the center of each side and work your way to the corners. At the corners, use your thumbnail or a toothpick or burnishing tool to miter the corners. Push the foil down on the long sides first (both ends) and then fold over the short sides.

Burnish the foil to insure good adhesion of the foil tape. I use the large end of a bone folder to do this.

Burnished and ready to solder.

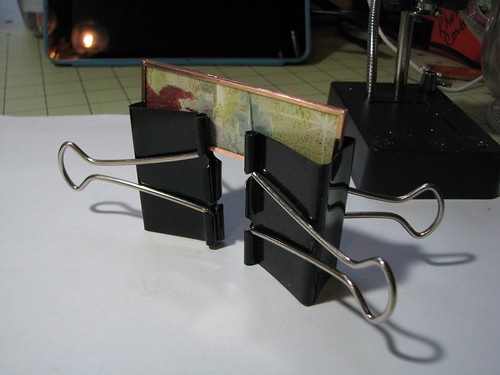

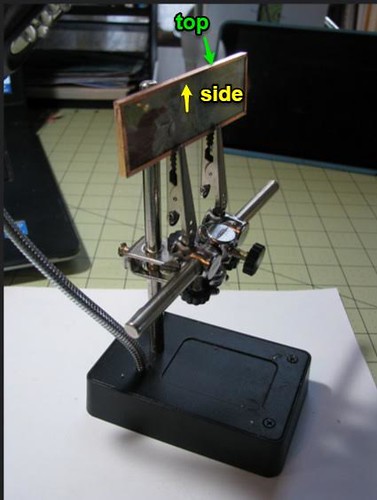

I use what is called a third hand to hold the ornament while I solder.

Binder clips work well, too.

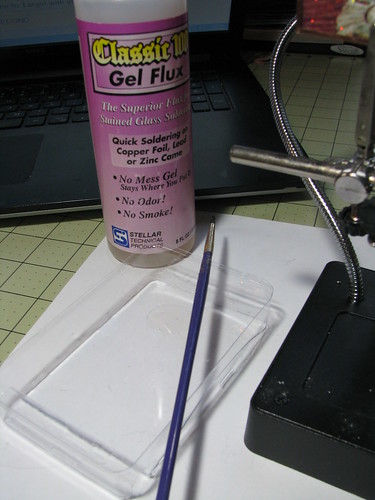

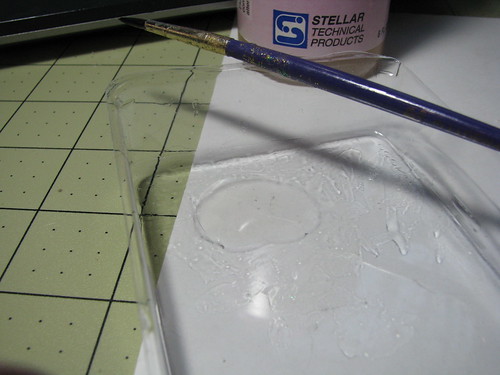

Flux is needed to make the solder adhere well to the copper foil.

You just need a tiny bit. Can you make out that clear circle in the clear container? It’s about the size of a nickel. That bottle is going to last me forever!

This picture is blurred, but you get the idea. Flux the length you plan to solder. Brush the flux on the top and the sides of the length.

Time to solder. Please watch some how-to-solder videos for hints and helps. Part of mastering it is practice, practice, practice.

Here’s a video on soldering. Soldering 101

And please read this soldering safety checklist. Safe Soldering Checklist

After I soldered the side of this ornament, the glass cracked. Probably from the heat. I’ve made about a hundred of these and this is only the second one that cracked. I used my craft knife to remove the foil.

After cleaning the replacement glass, replacing the foil, and burnishing it, I soldered it.

I don’t lay a piece on its side to solder as the example given in the video. Because 1/4″ tape is not very wide, laying down a bead of solder on the top will cause it to flow to the sides. (“Top” here refers to the up-facing portion of the foiled glass as it sits in the third hand. “Sides” means the sides of that one portion of glass.) Check both sides before taking the glass out of your third hand or clips to be sure both sides are well soldered. If not, touch the spots with your hot soldering iron and then melt the bead again across the top to even out the surface.

After you have soldered the top, it is time to place the jump ring. Hold the jump ring in the flat nose pliers, with the open spot to the bottom so it will be covered with solder when it’s done. Brush the join area on the ring with flux and flux the soldered area where it will be placed. Melt the solder on top the ornament, set the ring in place. Move the soldering iron back and forth to even out the solder. Check to see if the ring is well centered. Front to back, and side to side. If not, melt the solder, remove the ring and reset it, repeating the process.

Again, sorry about the blur…

Here’s one way to check for centered jump rings. Bull’s eye!

Or hold a ruler behind the piece before removing it from the third hand.

Add another jump ring to the other end, if you want to add a dangle. You can use the same size ring as on the top or use a smaller one.

When the jump ring is soldered into place, you can make a dangle or hang a charm.

Here are some different ways to finish your ornament. Beads, charms, bells, little ornaments meant for mini trees, etc. Some of these beads are from old necklaces that my sister picked up at thrift stores. Thrifting is a great way to find a wide assortment of beads.

This tutorial video shows how to make your own head pins, which are the wires you string beads on for a dangle. I use the first one she demonstrates. Jewelry Tutorial: How to Make Eyepins & Headpins : Three Types of Wire Wrapping

Make your head pin long enough to accommodate all the beads you want to string. I cut wire 2 1/2 inches long for my dangles.

This tutorial shows how to wrap the end of the dangle, making a loop for hanging it from the ornament. How to Wire Wrap a Bead Dangle : Wire Wrapping Tutorial – Jewelry Tutorial HQ

This is a good video about how to make your own jump rings. Making Your Own Jump Rings – Beaducation.com The part of the video you need to watch for making jump rings for our project starts at 4:50 and goes through 12:10.

After I attached the dangle to the ornament with a jump ring, I soldered the jump ring closed so the dangle wouldn’t fall off.

This is a picture of the jump ring before soldering. You can see where it comes together.

Close up.

Flux the jump ring and then solder it.

Closed jump ring. Now there is no chance of losing the dangle.

These are some of my favorites…the ones I plan to keep for myself.

I hope you give these a try. They are a lot of fun to make. My grands and I made some together. They picked their pictures and decided which beads to put on their dangles. They assembled the dangles and I did the rest. It’s not a child friendly craft, but we managed. Plenty of warnings about soldering iron safety (“NEVER touch it.”) and a helping hand with those parts they were able to handle. I wish I had taken a picture of their finished ornaments. Very cute!

If you have any questions about the process, please ask. I will do my best to clear things up. This was a long post. Thanks for hanging in there! I hope it inspires you to give soldering a try.

My soldered ornaments can be found in my Etsy shop. ChristmasNotebook

PS: Since writing this post, I have tried scalloped copper foil, which I really like. Read about it here: Scalloped Soldered Ornaments

~~Rhonda

4 Comments

Great tutorial. Do not burn your dad’s table top while doing this with your sisters.

Wow, thanks for all the details. These came out really great!

It wasn’t THIS sister who burned the table top…just sayin’.

LOVE these, wow!!!!!!!!!!!!!